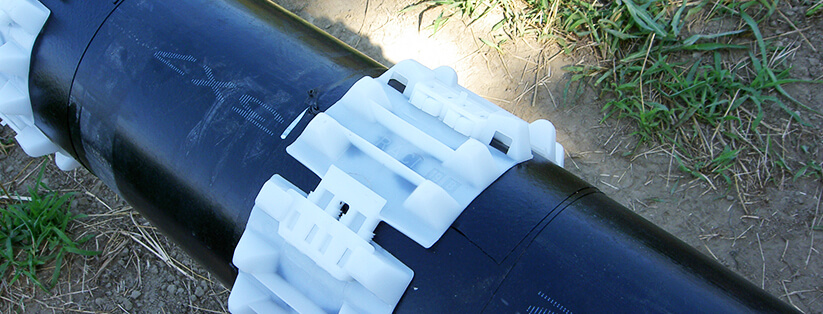

Raci spacers offer many advantages over the standard skid and strap application and over other models of manufactured spacers.

- Manufactured entirely out of high-density polyethylene with no metal bolts or attachments required

- Quickly and easily assembled by manually fitting elements one into the other

- Raci Pipe Spacers slide into casing with ease

- Tooth insertion method allows on site adjustment to fit a wide range of pipe diameters and coatings

- The Casing Spacers maintain continual long-term support for the carrier pipe and its contents

- Provide projections around the entire circumference of the carrier pipe.

A minimum of 1 projection for every 1 inch of carrier pipe O.D. - Provide long-term corrosion protection

- Can be installed on coated or plain concrete, ductile iron, plastic and steel pipe

Our HDPE casing spacers are manufactured by injections modling.

This gives it a high impact strength and a low coefficient of friction which exceeds industry standards.

Each HDPE spacer element represents a flexible section that has a toothed male butt strap at one end and an appropriately toothed female slot on the other end. Absolutely no metallic parts are involved in their assembly.

This design allows for on site adjustments for any variances within the O.D. range. Coupled with their flexibility they cover all types of pipe from O.D. range 1.65 inches (42 mm) and upward.

Physical characteristics

Raci High Density Polyethylene Spacers

Yield Strength

3625 PSI

25 N/mm2

ASTM D 638

Tensile Strength

2900 PSI

20 N/mm2

ASTM D 638

Elongation at break

200%

200%

ASTM D 638

Hardness shore D

65

65

ASTM D 2240

Min working temperature

-4˚ F

-20˚ C

Dielectric strength

>940 Kv/inch

>37 Kv/mm

ASTM 149/64

UVL stabilization

yes

yes